Special Purpose Machine

TCFAIS

Features & Specification

- Machine will be fabricated by rigid, Stress relived and fabricated structure

- Top of the base and center of the machine servo driven rotary table mounted, it’s divided into 8 stations

- The fixture designed by tube valve location v-block setup with automatic Pneumatic rotary Clamp

- All 5 Working Station using pneumatic Guide Cylinder setup for Up/down moment

- Provided Sensor for each Station up/down confirmation

- Station 1 – Manual Tube Valve loader

- Station 2 – Core Fixing ( Bowel Vibrator / Linear Vibrator and Feeder)

- Station 3 – Screw driver for Core tightening with Torque Control Pneumatic Screw Driver

- Station 4 – Partial Air Filling Station

- Station 5 – Full air Filling Station

- Station 6 – Un loader Station

- Provided Tube Value Loaded Confirmation – proximity Sensor

- Provided Digital Pressure Switch for working Air Pressure confirmation

- Provided Digital Pressure Switch for Pneumatic Screw Driver

- Provided Separate Air Accumulator with FR – unit for Air filling Station

- Provided Pneumatic 2 passage rotary union for rotary clamp air pressure input

- Provided 24 point electric Slip ring for Control all 8 Station Rotary clamp control

- Provided Digital part Count Controller

- Provided Touch panel for Parameter setting, monitoring system status, data logging

- Machine controlled by Servo system, PLC and HMI

- Provided FRL Unit for Pressure Regulating

- Provided Full machine Enclosure with transparent

Images of TCFAIS

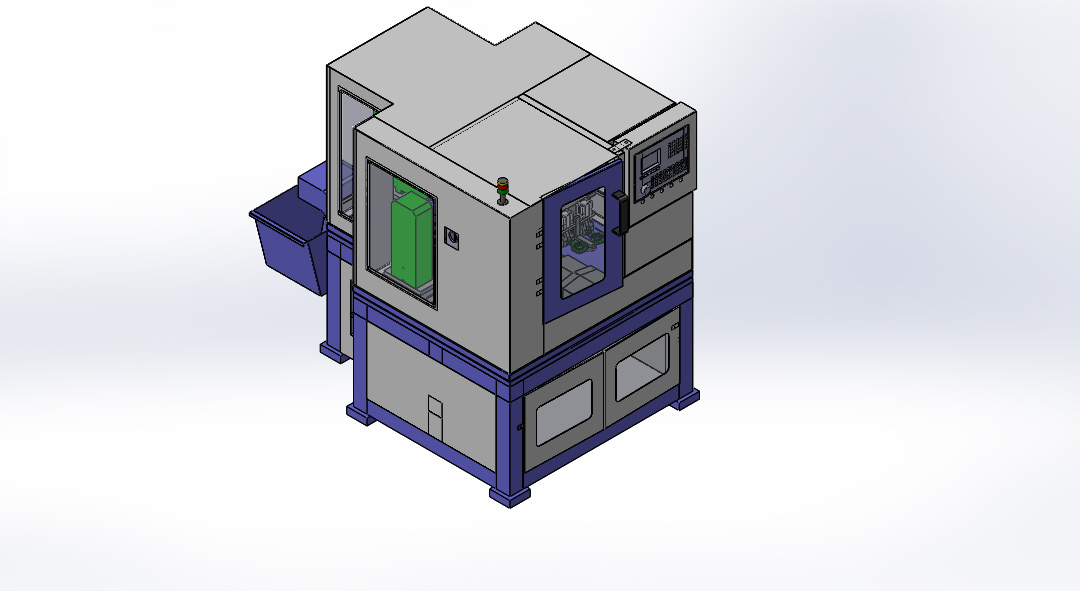

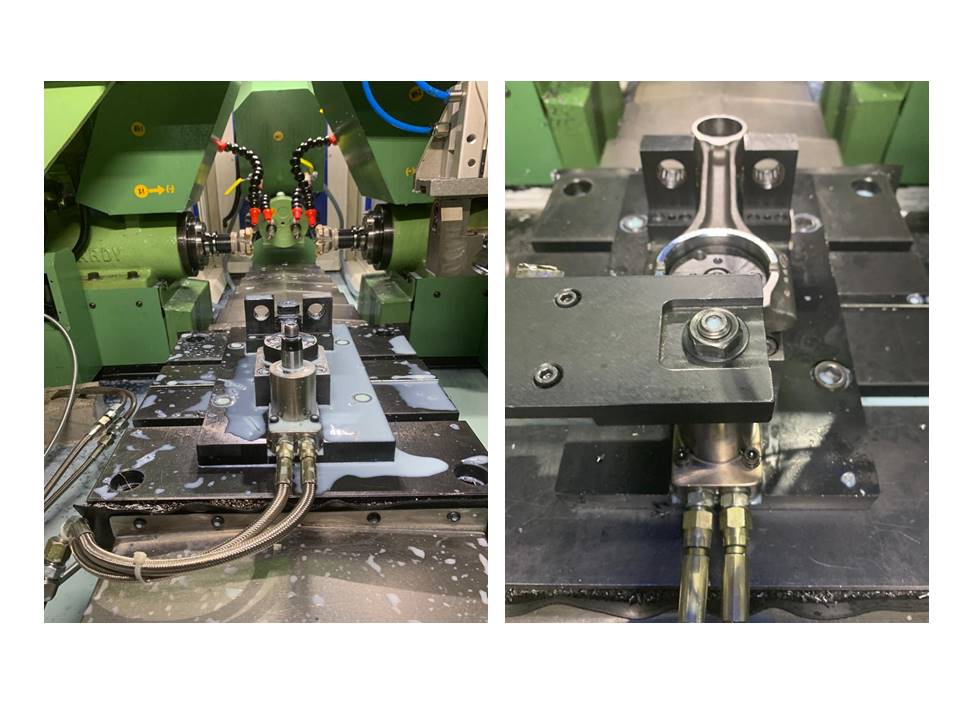

Conrod Milling and Spot Facing Machine

Features & Specification

- Machine will be fabricated by rigid, Stress relived and fabricated structure

- Top of the base, slide moment 3 axis bed and Fixed Multi Drilling head mounted

- A slide moment bed made by LM Guide ways & Ball Screw arrangement, Stroke moment X and Y axis – 80.0 mm

- Either side X and Y Axis Slide moment bed mounted on top of the base

- Above X and Y Axis bed mounted Milling Spindle head with BT40 spindle tapper

- Either side Milling spindle head run by 2.2 kw Spindle Induction motor and driven by timing pulley

- Milling Spindle Speed controlled by VFD, Speed 100 – 900 rpm

- Z – Axis Slide moment bed Perpendicularly mounted between X and Y axis , Stroke moment -900 .0 mm

- A slide moment run by Servo motor integrated with 5 axis CNC System

- Above the Z -axis Bed job Clamping Fixture setup mounted and Job Clamp by Hydraulic link Clamping Connecting crank end.

- Fixture setup specially made for Connecting rod back spot drilling

- Guide bush arrangement for Back Drilling

- Manual Component Loader

- Pendent for operator

- Standard G- Code Programming

- Special M-code given for Spindle milling spindle start cmd

- Special M-code for Job clamping and unclamping

- All the spindle VFD Communicated with CNC Controller to vary the speed

- Machine provided Complete enclosure setup

- Provided Chip Conveyor

- Provided Recirculating Coolant System and M-code given for Each spindle coolant ON/OFF

- Provided Centralized Lubrication system

- Provided Telescopic Cover for Z –axis

- Provided Hydraulic Power Pack @70 Bar

Features & Specification

- Machine will be fabricated by rigid, Stress relived and fabricated structure

- Both carriage and cross slide made by LM guide ways with ball screw arrangement.

- Carriage Stroke length 300.0 mm and Cross slide stroke length 150.0 mm

- Both Carriage(Z-axis) and Cross slide( X-axis) run by servo system

- Above the Cross slide T- slot mounted and tool post mounted above t-slot bed

- Spindle Driven by Induction motor with VFD

- Spindle motor and Spindle connected with Clutch and Break unit for Quick Stopping

- Spindle speed 100 – 1500 rpm

- Axis Rapid feed rate 7.5 m/min

- Both axis given telescopic cover for ball Screw and Guide ways Safety.

- Pneumatic Cylinder and Self Centering 3 jaw Chuck given for easy job Clamping

- Recirculating Coolant system

- Manual Centralized lubrication given for ball screw and LM Guide ways

- Enclosure given for Coolant and splash

- Easy Standard CNC G-code programming

- Foot Switch Easy Clamp and Unclamp

10 Station Drilling & Tapping Machine

Features & Specification

Machine will be fabricated by rigid, Stress relived and fabricated structure

Top of the base and center of the machine servo driven rotary table mounted, it’s divided into 10 stations

The fixture designed by component Reference location pin and Id Location, job clamped by manual clamp

Component having 11 number of M4 Tap operation, based on CD and PCD, we divided into no of drilling and tapping heads

Station 1 – Loading station – Manual Load component and manual clamp

- Station 2 – Multi head drilling station – this station having 4 numbers, Diameter 3.3 mm drill mounted on it with Guide bush arrangement, this drill head unit moment by vertical hydro pneumatic Feed control, drill Spindle run by 0.5 hp induction motor and driven by V belt arrangement.

- Station 3 – Multi head tapping station – this station having 4 numbers, M4 Tap mounted on it, this tap head unit moment Pitch control lead screw arrangement, drill Spindle run by 0.5 hp induction motor and driven by V belt arrangement.

Station 4 – Multi head drilling station – this station having 2 numbers, Diameter 3.3 mm drill mounted on it with Guide bush arrangement, this drill head unit moment by vertical hydro pneumatic Feed control, drill Spindle run by 0.5 hp induction motor and driven by V belt arrangement.

Station 5 – Multi head tapping station – this station having 2 numbers, M4 Tap mounted on it, this tap head unit moment Pitch control lead screw arrangement, drill Spindle run by 0.5 hp induction motor and driven by V belt arrangement.

- Station 6 – Multi head drilling station – this station having 3 numbers, Diameter 3.3 mm drill mounted on it with Guide bush arrangement, this drill head unit moment by vertical hydro pneumatic Feed control, drill Spindle run by 0.5 hp induction motor and driven by V belt arrangement.

Station 7 – Multi head tapping station – this station having 3 numbers, M4 Tap mounted on it, this tap head unit moment Pitch control lead screw arrangement, drill Spindle run by 0.5 hp induction motor and driven by V belt arrangement.

Station 8 – Multi head drilling station – this station having 2 numbers, Diameter 3.3 mm drill mounted on it with Guide bush arrangement, this drill head unit moment by vertical hydro pneumatic Feed control, drill Spindle run by 0.5 hp induction motor and driven by V belt arrangement.

Station 9 – Multi head tapping station – this station having 2 numbers, M4 Tap mounted on it, this tap head unit moment Pitch control lead screw arrangement, drill Spindle run by 0.5 hp induction motor and driven by V belt arrangement.

Station 10 – Unload station

Total Machine controlled by Servo system, PLC and HMI

Each Drilling station given read switch for position control

Each Tapping Station given Proximity sensor for Position control

Machine given Manual Centralized lubrication given all drilling and tapping heads

Recirculating Coolant System

Machine Provided with Complete enclosure.

2 Station Drilling & Tapping Machine

Features & Specification

- Rigid and Machined Cast ion bed with base

- Top of the base constructed a slide moment Carriage arrangement

- Slide moment made by LM Guide ways and Ball Screw arrangement, carriage stroke moment 500.0 mm

- The fixture designed by component Reference location and full proof, job clamped by manual toggle clamp on either side, this fixture setup mounted above the carriage.

- Multi Drilling and tapping spindle head mounted above the base on either side (RH side Multi Drill spindle head / LH side Multi Tapping Head)

- Multi drill spindle head having ER11 Collet

- Multi tapping Spindle Suitable for TR16 Tapping Adaptor

- Carriage Slide moment run by servo motor

- Multi head drilling station – this station having 2 numbers, Diameter 2.5 mm drill mounted on it with Guide bush arrangement, this drill head unit moment by vertical hydro pneumatic Feed control, drill Spindle run by 0.5 hp inductions motor and driven by V belt arrangement.

- Multi head tapping station – this station having 2 numbers, M3 Tap mounted on it, this tap head unit moment Pitch control lead screw arrangement, drill Spindle run by 0.5 hp induction motor and driven by V belt arrangement.

- Total Machine controlled by Servo system, PLC and HMI

- Touch panel given for Operator parameter setting of Position and Feed rate

- Each Drilling station given read switch for position control

- Each Tapping Station given Proximity sensor for Position control

- Multi spindle head having easy changing arrangement of different jobs

- Machine given Manual Centralized lubrication given for axis guide ways, Ball screw nut and all drilling and tapping heads

- Recirculating Coolant System

- Machine provided with coolant splash guard.

Features & Specification

- Rigid and Machined Cast ion bed with base

- Top of the base rigid, Stress relived and fabricated structure for Carriage and Cross Slide

- Both carriage and cross slide made by LM guide ways with ball screw arrangement.

- Carriage Stroke length 300.0 mm and Cross slide stroke length 500.0 mm

- Both Carriage(Z-axis) and Cross slide( X-axis) run by servo system

- Above the Cross slide T- slot mounted

- Live tool Special Cutter Mounted and Driven by induction motor

- Main Spindle Driven by Induction motor with VFD

- Main Spindle Speed Controlled by VFD , Speed 100 – 600 rpm

- Special Cutter Back side, Mounted Blower setup for collecting the Filament

- For job clamping, provided manual 3 jaw Self Centering Chuck

- Standard G- Code Programming

- Provided Standard CNC lathe Controller for machine operation

- Provided Bellow cover for Axis Guide Way and Ball Screw Safety

- Swing Over Bed 800.0 mm

Features & Specification

- Machine will be fabricated by rigid, Stress relived and fabricated structure

- Top of the base rigid, Stress relived and fabricated structure for Carriage and Cross Slide

- Both carriage and cross slide made by LM guide ways with ball screw arrangement.

- Carriage Stroke length 1200.0 mm and Cross slide stroke length 400.0 mm

- Both Carriage(Z-axis) and Cross slide( X-axis) run by servo system

- Above the Cross slide T- slot mounted

- Live tool Special Cutter Mounted and Driven by induction motor

- Main Spindle Driven by Induction motor with VFD

- Main Spindle Speed Controlled by VFD , Speed 100 – 1200 rpm

- Special Cutter Back side, Mounted Blower setup for collecting the Filament

- For job clamping, provided manual 3 jaw Self Centering Chuck

- Provided Pneumatic tail stock quill moment

- Provided Bellow cover for Axis Guide Way and Ball Screw Safety

- Standard G- Code Programming

- Provided Standard CNC lathe Controller for machine operation

- Swing Over Bed 400.0 mm

- Provided Foot Switch for tail Control

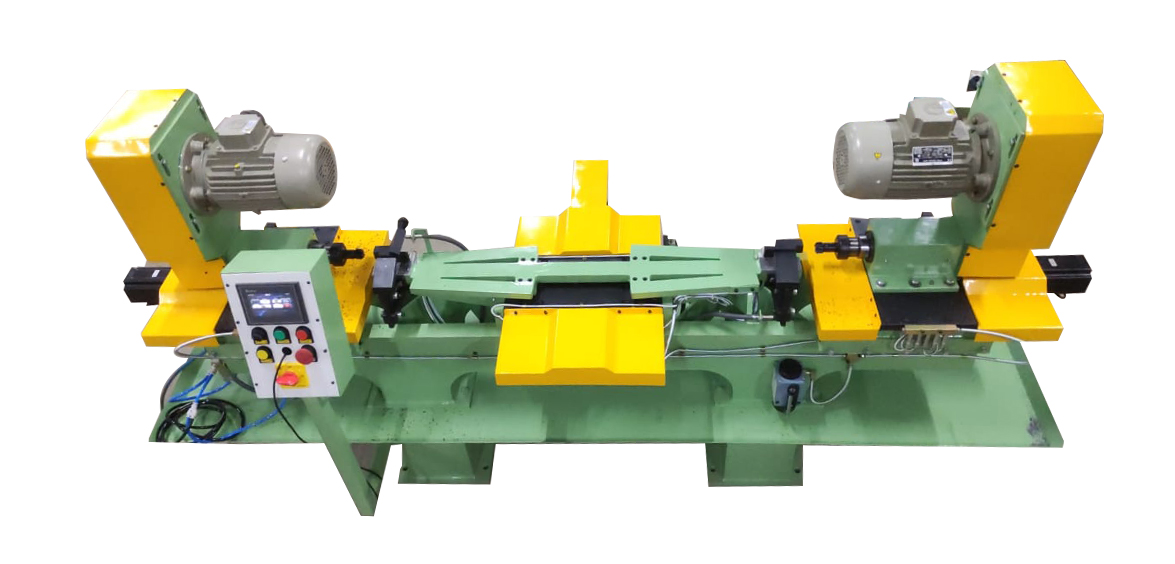

Features & Specification

- Machine will be fabricated by rigid, Stress relived and fabricated structure

- Top of the base, slide moment 3 axis bed mounted

- A slide moment bed made by LM Guide ways & Ball Screw arrangement, Stroke moment 150.0 mm

- Either side X1 and X2 Axis Slide moment bed mounted on top of the base

- Above X1 and X2 Axis bed mounted Milling Spindle head with ER40 spindle tapper

- Either side Milling spindle head run by 1.5 kw Spindle Induction motor and driven by V-pulley

- Y Axis Slide moment bed Perpendicularly mounted between X1 and X2 axis

- A slide moment run by Stepper motor with PLC System

- Above the Y-axis Bed job Clamping Fixture setup mounted and Job Clamp by Pneumatic Toggle Clamping to the both the ends with manual job reference stopper

- Manual Component Loader

- Job Reference stopper release Confirmation

- Job Clamp Confirmation

- Pendent for operator

- Touch Panel given for Component offset setting, Position, Feed rate Parameters settings and tool compensation settings.

- Splash guard for material cutting area

“Tested successfully the project and result has excellent on output. Appreciate the team to thumbs up”

Thanga Krishnan